|

|||||||||||||||||||

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||

CLEAR PVC LOW PRESSURE TUBING

| PART NUMBER | TRADE SIZE | I.D. | O.D. | WALL THICKNESS | WORKING P.S.I. | PKG. QTY. |

| PVTC-125-031 | 1/8 | .125 | .187 | .031 | 65 | 100' |

| PVTC-125-062 | 1/8 | .125 | .250 | .062 | 78 | 100' |

| PVTC-187-062 | 3/16 | .187 | .312 | .062 | 70 | 100' |

| PVTC-250-062 | 1/4 | .250 | .375 | .062 | 75 | 100' |

| PVTC-312-062 | 5/16 | .312 | .437 | .062 | 61 | 100' |

| PVTC-312-093 | 5/16 | .312 | .500 | .093 | 63 | 100' |

| PVTC-375-062 | 3/8 | .375 | .500 | .062 | 47 | 100' |

| PVTC-375-093 | 3/8 | .375 | .562 | .093 | 65 | 100' |

| PVTC-500-062 | 1/2 | .500 | .625 | .062 | 70 | 100' |

| PVTC-500-125 | 1/2 | .500 | .750 | .125 | 73 | 100' |

| PVTC-625-062 | 5/8 | .625 | .750 | .062 | 42 | 100' |

| PVTC-625-125 | 5/8 | .625 | .875 | .125 | 68 | 100' |

| PVTC-750-062 | 3/4 | .750 | .875 | .062 | 35 | 100' |

| PVTC-750-125 | 3/4 | .750 | 1.000 | .125 | 62 | 50' |

| PVTC-1000-125 | 1 | 1.000 | 1.250 | .125 | 68 | 50' |

EXTRUDED

GROMMETING

Used to line panel edges and knockouts where the chafing of pass thru wire bundles is a concern. In most applications, extruded cut grommeting will grip tightly by itself. Also available in molded Tefzel material and in MS-21266 Series natural nylon molded grommeting.

| Part Number | Material | Width, measured at top opening or maximum panel thickness | Grommeting Height | Grommeting Bottom Width | Package Quantity |

| GRNY-040-9-C | Natural Nylon | .040 | .190 | .125 | 100 FEET |

| GRNY-052-9-C | Natural Nylon | .052 | .190 | .125 | 100 FEET |

| GRNY-062-9-C | Natural Nylon | .062 | .200 | .170 | 100 FEET |

| GRNY-085-9-C | Natural Nylon | .085 | .200 | .170 | 100 FEET |

| GRNY-100-9-C | Natural Nylon | .100 | .220 | .210 | 100 FEET |

| GRNY-125-9-C | Natural Nylon | .125 | .220 | .205 | 100 FEET |

| GRNY-187-9-C | Natural Nylon | .187 | .270 | .275 | 100 FEET |

| GRNY-250-9-C | Natural Nylon | .250 | .280 | .370 | 100 FEET |

| GRNY-040-0-C | UV Black Nylon | .040 | .190 | .125 | 100 FEET |

| GRNY-052-0-C | UV Black Nylon | .052 | .190 | .125 | 100 FEET |

| GRNY-062-0C | UV Black Nylon | .062 | .200 | .170 | 100 FEET |

| GRNY-085-0-C | UV Black Nylon | .085 | .200 | .170 | 100 FEET |

| GRNY-100-0-C | UV Black Nylon | .100 | .220 | .210 | 100 FEET |

| GRNY-125-0-C | UV Black Nylon | .125 | .220 | .205 | 100 FEET |

| GRNY-187-0-C | UV Black Nylon | .187 | .270 | .275 | 100 FEET |

| GRNY-250-0-C | UV Black Nylon | .250 | .280 | .370 | 100 FEET |

| GRPE-040-9-C | Polyethylene | .040 | .190 | .125 | 100 FEET |

| GRPE-052-9-C | Polyethylene | .052 | .190 | .125 | 100 FEET |

| GRPE-062-9-C | Polyethylene | .062 | .200 | .170 | 100 FEET |

| GRPE-085-9-C | Polyethylene | .085 | .200 | .170 | 100 FEET |

| GRPE-100-9-C | Polyethylene | .100 | .220 | .210 | 100 FEET |

| GRPE-125-9-C | Polyethylene | .125 | .220 | .205 | 100 FEET |

| GRPE-187-9-C | Polyethylene | .187 | .270 | .275 | 100 FEET |

| GRPE-250-9-C | Polyethylene | .250 | .280 | .370 | 100 FEE |

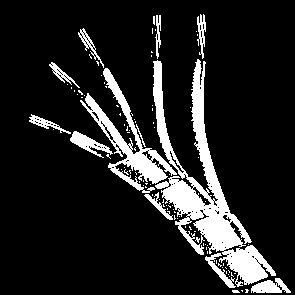

SPIRAL CABLE

WRAP

Spiral wrap is designed to be used to protect wire bundles and hose from chafing. Right hand or clockwise cut polyethylene spiral wrap can either be installed gapped for greater flexibility, or butted for maximum abrasion resistance. Also available in Teflon, Flame Retardant Polyethylene and a limited number of fluorescent safety colors.

| Part Number | Material | O.D. | Pitch | Wall Thickness | Min. Bundle Dia.. | Max. Bundle Dia. |

| SW-03-PEN | NATURAL POLYETHYLENE | .187 | .240 | .040 | .125 | 1.500 |

| SW-04-PEN | NATURAL POLYETHYLENE | .250 | .375 | .045 | .188 | 2.000 |

| SW-06-PEN | NATURAL POLYETHYLENE | .375 | .438 | .052 | .313 | 3.000 |

| SW-08-PEN | NATURAL POLYETHYLENE | .500 | .563 | .062 | .375 | 4.000 |

| SW-10-PEN | NATURAL POLYETHYLENE | .625 | .625 | .062 | .625 | 4.500 |

| SW-12-PEN | NATURAL POLYETHYLENE | .750 | .750 | .065 | .750 | 5.000 |

| SW-16-PEN | NATURAL POLYETHYLENE | 1.000 | 1.110 | .070 | 1.000 | 7.000 |

| SW-03-PEB | UV BLACK POLYETHYLENE | .187 | .240 | .040 | .125 | 1.500 |

| SW-04-PEB | UV BLACK POLYETHYLENE | .250 | .375 | .045 | .188 | 2.000 |

| SW-06-PEB | UV BLACK POLYETHYLENE | .375 | .438 | .052 | .313 | 3.000 |

| SW-08-PEB | UV BLACK POLYETHYLENE | .500 | .563 | .062 | .375 | 4.000 |

| SW-10-PEB | UV BLACK POLYETHYLENE | .625 | .625 | .062 | .625 | 4.500 |

| SW-12-PEB | UV BLACK POLYETHYLENE | .750 | .750 | .065 | .750 | 5.000 |

| SW-16-PEB | UV BLACK POLYETHYLENE | 1.000 | 1.110 | .070 | 1.000 | 7.000 |

CONVOLUTED

SLIT LOOM

Please note: for bulk convoluted slit loom, please drop the "-C" suffix from the part number, which calls out pre-cut 100 foot rolls. Operating temperature range for polyethylene split loom is -40║ F to 200║ F. Nylon split loom, also available by special order, has an operating temperature range of -40║ F - 300║ F. We also carry fire retardant polypropylene (teal green in color) in several sizes; please contact ICG Corporation for additional details.

| Part Number | FOR I.D. | PACKAGED LENGTH | BULK QUANTITY / LENGTH |

| SLP-025-C | 1/4" | 100' | 2500' |

| SLP-037-C | 3/8" | 100' | 1500' |

| SLP-050-C | 1/2" | 100' | 900' |

| SLP-062-C | 5/8" | 100' | 600' |

| SLP-075-C | 3/4" | 100' | 500' |

| SLP-100-C | 1" | 50' | 250' |

| SLP-125-C | 1-1/4" | N/A | 200' |

| SLP-150-C | 1-1/2" | N/A | 150' |

| SLP-200-C | 2" | 100' | 100' |

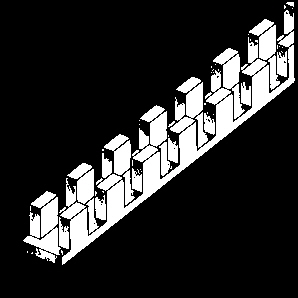

WIRING DUCT

/ PANEL CHANNEL AND ACCESSORIES

OPEN

SLOT DUCTING

OPEN

SLOT DUCTING

Open Slot Ducting -

our Open Slot Wiring Duct has a snap-back wire retention feature to trap

installed wires and is available in both rigid vinyl (PVC) and lightweight

chlorine-free Noryl«. Straight deep slots allow larger wire sizes all the way to

the bottom. All edges are buffed smooth to minimize wire chafing.

Catalog Number must be completed by adding suffix for color: LG6 for Gray, BK6

for Black, WH6 for white. Example: TBNA200X200LG6 and TBNAC200LG6 is a 2”

x 2” gray duct and a 2” gray cover. For Noryl« covers, add suffix “CF6”.

Standard lengths are 6 feet. To order Adhesive-backed Duct, add suffix

A to Catalog Number. Example: NA200x200LG6A is a 2” x 2” gray duct with adhesive

backing. Shelf life for adhesive is 1 year.

Note: Noryl« duct is available in oyster white only. Noryl« is a registered trademark of General Electric Co. Vinyl duct is UL Recognized , CSA Certified and meets the JIC requirements.

| Vinyl Catalog Number | Noryl« Part Number | Uses Cover Part No. | Nom. Width | Nom. Height | A | B | C | D | E | F | H | I | J |

| TBNA050X050 | N/A | TBNAC050 | .5 | .50 | .62 | .50 | .75 | .56 | .625 | .375 | .5 | - | |

| TBNA050X100 | N/A | TBNAC050 | .5 | 1.00 | .62 | 1.00 | .75 | 1.10 | .73 | .63 | .5 | .31 | |

| TBNA050X125 | N/A | TBNAC050 | .5 | 1.25 | .62 | 1.25 | .75 | 1.35 | .73 | .52 | .5 | .31 | |

| TBNA075X075 | N/A | TBNAC075 | .75 | .75 | .86 | .75 | 1.06 | .88 | .625 | .375 | .5 | - | |

| TBNA075X125 | N/A | TBNAC075 | .75 | 1.25 | .86 | 1.25 | 1.06 | 1.35 | .73 | .52 | .5 | .31 | |

| TBNA075X150 | N/A | TBNAC075 | .75 | 1.50 | .86 | 1.50 | 1.06 | 1.60 | .73 | 1.00 | .5 | .31 | |

| TBNA100X100 | TBNA100X100CF6 | TBNAC100 | 1.00 | 1.00 | 1.13 | 1.00 | 1.38 | 1.10 | .73 | .52 | .5 | .31 | |

| TBNA100X125 | TBNA100X125CF6 | TBNAC100 | 1.00 | 1.25 | 1.13 | 1.25 | 1.38 | 1.25 | .73 | .52 | .5 | .31 | |

| TBNA100X150 | TBNA100X150CF6 | TBNAC100 | 1.00 | 1.50 | 1.13 | 1.50 | 1.38 | 1.60 | .73 | 1.00 | .5 | .31 | |

| TBNA100X200 | TBNA100X200CF6 | TBNAC100 | 1.00 | 2.00 | 1.18 | 2.00 | 1.38 | 2.10 | .73 | 1.25 | .5 | .38 | |

| TBNA100X300 | TBNA100X300CF6 | TBNAC100 | 1.00 | 3.00 | 1.18 | 3.00 | 1.38 | 3.10 | 1.00 | 2.25 | .5 | .38 | |

| TBNA100X400 | TBNA100X400CF6 | TBNAC100 | 1.00 | 4.00 | 1.20 | 4.00 | 1.38 | 4.10 | 1.00 | 3.25 | .5 | .38 | |

| TBNA150X100 | TBNA150X100CF6 | TBNAC150 | 1.50 | 1.00 | 1.63 | 1.00 | 1.88 | 1.10 | .73 | .52 | .5 | .31 | |

| TBNA150X150 | N/A | TBNAC150 | 1.50 | 1.50 | 1.63 | 1.50 | 1.88 | 1.60 | .73 | 1.00 | .5 | .31 | |

| TBNA150X200 | TBNA150X200CF6 | TBNAC150 | 1.50 | 2.00 | 1.68 | 2.00 | 1.88 | 2.10 | .73 | 1.25 | .5 | .38 | |

| TBNA150X300 | TBNA150X300CFC6 | TBNAC150 | 1.50 | 3.00 | 1.68 | 3.00 | 1.88 | 3.10 | 1.00 | 2.25 | .5 | .38 | |

| TBNA150X400 | TBNA150X400CF6 | TBNAC150 | 1.50 | 4.00 | 1.70 | 4.00 | 1.88 | 4.10 | 1.00 | 3.25 | .5 | .38 | |

| TBNA200X100 | TBNA200X100CF6 | TBNAC200 | 2.00 | 1.00 | 2.13 | 1.00 | 2.38 | 1.10 | .73 | .52 | .5 | ||

| TBNA200X150 | TBNA200X150CF6 | TBNAC200 | 2.00 | 1.50 | 2.13 | 1.50 | 2.38 | 1.60 | .73 | 1.00 | .5 | ||

| TBNA200X200 | TBNA200X200CF6 | TBNAC200 | 2.00 | 2.00 | 2.18 | 2.00 | 2.38 | 2.10 | .73 | 1.25 | .5 | ||

| TBNA200X300 | TBNA200X300CF6 | TBNAC200 | 2.00 | 3.00 | 2.18 | 3.00 | 2.38 | 3.10 | 1.00 | 2.25 | .5 | ||

| TBNA200X400 | TBNA200X400CF6 | TBNAC200 | 2.00 | 4.00 | 2.20 | 4.00 | 2.38 | 4.10 | 1.00 | 3.25 | .5 | ||

| TBNA200X500 | TBNA200X500CF6 | TBNAC200 | 2.00 | 5.00 | 2.20 | 5.00 | 2.38 | 5.10 | 1.50 | 4.25 | .75 | ||

| TBNA250X300 | N/A | TBNAC250 | 2.50 | 3.00 | 2.68 | 3.00 | 2.88 | 3.10 | 1.00 | 2.25 | .5 | ||

| TBNA300X100 | N/A | TBNAC300 | 3.00 | 1.00 | 3.13 | 1.00 | 3.38 | 1.10 | .73 | .52 | .5 | ||

| TBNA300X125 | TBNA300X125CF6 | TBNAC300 | 3.00 | 1.25 | 3.13 | 1.25 | 3.38 | 1.35 | .73 | .52 | .5 | ||

| TBNA300X200 | N/A | TBNAC300 | 3.00 | 2.00 | 3.18 | 2.00 | 3.38 | 2.10 | .73 | 1.25 | .5 | ||

| TBNA300X300 | TBNA300X300CF6 | TBNAC300 | 3.00 | 3.00 | 3.18 | 3.00 | 3.38 | 3.10 | 1.00 | 2.25 | .5 | ||

| TBNA300X400 | TBNA300X400CF6 | TBNAC300 | 3.00 | 4.00 | 3.20 | 4.00 | 3.38 | 4.10 | 1.00 | 3.25 | .5 | ||

| TBNA300X500 | TBNA300X500CF6 | TBNAC300 | 3.00 | 5.00 | 3.20 | 5.00 | 3.38 | 5.10 | 1.50 | 4.25 | .75 | ||

| TBNA400X100 | N/A | TBNAC400 | 4.00 | 1.00 | 4.20 | 1.00 | 4.38 | 1.10 | .73 | .52 | .5 | ||

| TBNA400X200 | TBNA400X200CF6 | TBNAC400 | 4.00 | 2.00 | 4.20 | 2.00 | 4.38 | 2.10 | .73 | 1.25 | .5 | ||

| TBNA400X300 | TBNA400X300CF6 | TBNAC400 | 4.00 | 3.00 | 4.18 | 3.00 | 4.38 | 3.10 | 1.00 | 2.25 | .5 | ||

| TBNA400X400 | TBNA400X400CF6 | TBNAC400 | 4.00 | 4.00 | 4.20 | 4.00 | 4.38 | 4.10 | 1.00 | 3.25 | .5 | ||

| TBNA400X500 | TBNA400X500CF6 | TBNAC400 | 4.00 | 5.00 | 4.20 | 5.00 | 4.38 | 5.10 | 1.50 | 4.25 | .75 |

ROUND

HOLE DUCTING

ROUND

HOLE DUCTING

Round Hole Ducting - our Round Hole Wiring Duct features the

maximum number of wire holes consistent with sound engineering practice, plus

the benefit of positive wire placement and greater rigidity than open-top duct.

Used in applications where wire breakouts must be kept at a certain height.

Round Hole Duct is UL Recognized, CSA Certified and meets JIC requirements.

Colors are gray, black or white. Covers for all duct widths are described

below. Cover Catalog Number is listed adjacent to the duct Catalog Number

in the tables in this section.

Catalog Number must be completed by adding suffix for color: LG6 for Gray, BK6 for Black, WH6 for white. Example: TBRH200X200LG6 and TBNAC200LG6 is a 2” x 2” gray duct and a 2” gray cover. Standard lengths are 6 feet. Adhesive backed duct in round hole style is a custom order.

| Vinyl Catalog Number | Uses Cover Part No. | Nom. Width | Nom. Height | A | B | C | D |

| TBR100X100LG6 | C100LG6 | 1.00" | 1.00" | .98 | 1.18 | ||

| TBR100X150LG6 | C100LG6 | 1.00" | 1.50" | .98 | 1.57 | ||

| TBR100X225LG6 | C100LG6 | 1.00" | 2.25" | .98 | 2.36 | ||

| TBR100X300LG6 | C100LG6 | 1.00" | 3.00" | .98 | 3.15 | ||

| TBR100X400LG6 | C100LG6 | 1.00" | 4.00" | .98 | 3.94 | ||

| TBR150X150LG6 | C150LG6 | 1.50" | 1.50" | 1.57 | 1.57 | ||

| TBR150X225LG6 | C150LG6 | 1.50" | 2.25" | 1.57 | 2.36 | ||

| TBR150X300LG6 | C150LG6 | 1.50" | 3.00" | 1.57 | 3.15 | ||

| TBR150X400LG6 | C150LG6 | 1.50" | 4.00" | 1.57 | 3.94 | ||

| TBR225X225LG6 | C225LG6 | 2.25" | 2.25" | 2.36 | 2.36 | ||

| TBR225X300LG6 | C225LG6 | 2.25" | 3.00" | 2.36 | 3.15 | ||

| TBR225X400LG6 | C225LG6 | 2.25" | 4.00" | 2.36 | 3.94 | ||

| TBR300X300LG6 | C300LG6 | 3.00" | 3.00" | 3.15 | 3.15 | ||

| TBR300X400LG6 | C300LG6 | 3.00" | 4.00" | 3.15 | 3.94 | ||

| TBR400X300LG6 | C400LG6 | 4.00" | 3.00" | 3.94 | 3.15 | ||

| TBR400X400LG6 | c400lg6 | 4.00" | 4.00" | 3.94 | 3.94 |

CLOSED

WALL DUCTING

CLOSED

WALL DUCTING

Closed Wall Ducting - our Solid Wall Wiring Duct is available in both rigid vinyl (PVC) and lightweight chlorine free Noryl«. Solid Wall Duct is UL Recognized, CSA Certified and meets JIC requirements. Colors are gray, black or white. Covers for duct widths are described below. Cover Catalog Number is listed adjacent to the duct Catalog Number in the tables in this section.

Catalog Number must be completed by adding suffix for color: LG6 for Gray, BK6 for Black, WH6 for white.

Example: TBNAS200X200LG6 and TBNASC200LG6 is a 2” x 2” gray duct and a 2” gray cover. For Noryl« covers, add suffix “CF6”. Standard lengths are 6 feet. Adhesive backed duct in solid wall style is a custom order.

| Vinyl Catalog Number | Noryl« Part Number | Uses Cover Part No. | Nom. Width | Nom. Height | A | B | C | D |

| coming soon! | ||||||||

Ducting Cover - Patented “no slip” snap-on cover interlocks

with duct sidewalls to prevent vibration slippage. Angled and interlocked

lips on duct cover and sidewalls enable cover to be snapped on, yet prevent

it from popping off.

Covers are available in rigid vinyl (PVC) and lightweight chlorine-free

Noryl« for each duct width. Vinyl colors are gray, black or white.

Noryl« color is oyster white only. Cover Catalog Number is

listed adjacent to the duct Catalog Number in the tables in this section

above.